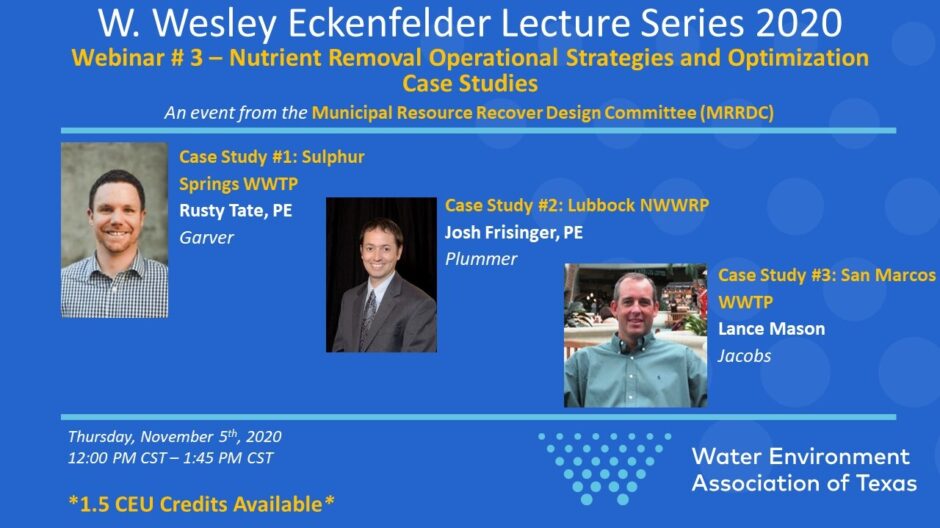

Case Study #1: Sulphur Springs WWTP

The City of Sulphur Springs WWTP faced an immediate need for increased nitrification capacity due to significant industrial contributors discharging very high BOD into the collection system. Based on organic loading, the original 5.4 MGD plant was essentially capable of 3.0 MGD and needed a capacity upgrade as well as consideration given to future effluent phosphorus limits. Through an extensive flow and loading evaluation, Garver identified the significant industrial contributors that required upgrades capable of treating raw BOD influent above 600 mg/l. Utilizing Hydromantis’ GPS-X biological modeling software, Garver investigated an array of treatment alternatives to recover the value of existing tankage that could be retrofitted for increased capacity. The resulting project retrofitted existing mechanical aerators with fine bubble diffusers, complete with tapered aeration, plug flow reconfiguration, and selector zones. Implementation of a phased BNR approach was able to save the City millions of dollars in electrical costs, by implementing anoxic basins with mixers in the first stage of treatment in lieu of fully aerated basins.

Case Study #2: Lubbock NW WRP

This case study will discuss the phased approach to nutrient removal at the newly constructed Northwest Water Reclamation Plant in the City of Lubbock. The plant was envisioned as a minimally staffed 3 MGD plant in the initial phase, with no on-site solids processing facilities. This presentation will discuss how these factors led to a design that includes a combination of membrane bioreactors with chemical phosphorus removal, while leaving the door open to future biological nutrient removal. Results from the first two years of operation will be discussed including ammonia and total phosphorus removal, as well as a look at the chemical usage required to meet the phosphorus limit.

Case Study #3: San Marcos WWTP

The City of San Marcos, Texas wastewater treatment plant is permitted for a daily average flow of 9-million gallons per day (MGD) and is required to maintain a 30-day average total phosphorus concentration of less than 1.0 mg/L in the final effluent. This facility is designed for an A/O enhanced biological phosphorus removal (EBPR) process and is equipped with a ferric chloride dosing system for chemical precipitation of phosphorus. A main contributor in terms of flow and load to the San Marcos wastewater treatment plant is Texas State University which is now the fourth largest university in the state of Texas. During time periods of summer break and the holidays, the operations staff saw significant drops in the influent cBOD and correlated floc/filter COD values.

Historically the plant’s biological removal of phosphorus proved to be inconsistent and the facility staff used ferric chloride to precipitate the phosphorus chemically. In 2014, Jacobs embarked on a study to improve the EBPR process to reduce the chemical costs associated with meeting the discharge permit requirements. Through this endeavor significant reductions in ferric chloride have been demonstrated as well as reductions in nitrogen and phosphorus from the final effluent stream through biological treatment.

Rusty Tate is the Process Group Leader at Garver and has spent 13 years modeling wastewater treatment processes to improve their safety and efficiency. He utilizes models to look at different potential process arrangements to gauge the best results, while guiding designs to make plans more efficient and easier to implement, which can increase capacity and performance. Having worked as an operator, Rusty understands needs and concerns of operations and maintenance staff. His insight into the day-to-day procedures allows him to construct designs in a manner that is easily implementable for operators, increases operator safety, and improves overall plant efficiency.

Josh Frisinger is the Northwest Wastewater team leader with Plummer Associates. Josh is a graduate of Cornell University and the University of Texas at Arlington. He has been with Plummer for 19 years. During that time, he has worked on dozens of wastewater treatment plant evaluations and designs, including working on the design and construction phases of the new 3 MGD Northwest Water Reclamation Plant that will be the topic of his presentation today.

Lance Mason has 25-years of experience in water and wastewater operations, including process optimization, operations training, water and wastewater facilities’ and staff management, process troubleshooting, and facility start-up/commissioning. Additionally, he has experience in wastewater plant mathematical modeling and on-line monitoring instrumentation. Mr. Mason has been involved in numerous projects on five different continents dealing with wastewater process, chemistry, instrumentation, mathematical modeling and energy efficiency. Mr. Mason also gained teaching experience through graduate school and as an adjunct professor at a community college.

Currently Mr. Mason’s main focus as an operations consultant is working with operations staffs all around the country to provide them with the learning tools needed to optimize and/or troubleshoot the process to achieve the highest level of efficiency while maintaining regulatory compliance for water quality.

Thank you to our Sponsors!

- Black and Veatch

- CP&Y

- Garver

- Plummer